In modern industrial safety protection systems, flame-retardant thermal insulation protective materials must not only possess excellent fire resistance, thermal insulation, and mechanical properties, but also adapt to complex and ever-changing construction site conditions. Traditional high-performance coatings often have stringent requirements for application methods—either requiring professional spraying or exhibiting slow drying and poor leveling, making it difficult to guarantee quality under manual operation. However, the new generation of two-component high-solids-content flame-retardant special topcoats successfully resolves this contradiction: it supports manual brushing, traditional air spraying, and is compatible with various processes such as high-pressure airless or air-assisted spraying. Regardless of the method used, it can form a high-strength, scratch-resistant, corrosion-resistant, seamless, and aesthetically pleasing continuous protective layer. This dual capability of "flexible application" and "consistent film formation" stems from its unique material design and rheology control technology.

This material uses a room temperature or medium temperature rapid curing system, with surface drying time as short as 10–30 minutes. Rapid cross-linking not only shortens the construction period, but more importantly, it quickly "freezes" the coating morphology, avoiding performance fluctuations caused by changes in environmental temperature and humidity or construction intervals. For example, in outdoor steel structure coating, even in the event of a light breeze or slight dust, the cured surface effectively isolates external interference, ensuring the inner layer continues to react stably, ultimately achieving uniform performance across the entire thickness.

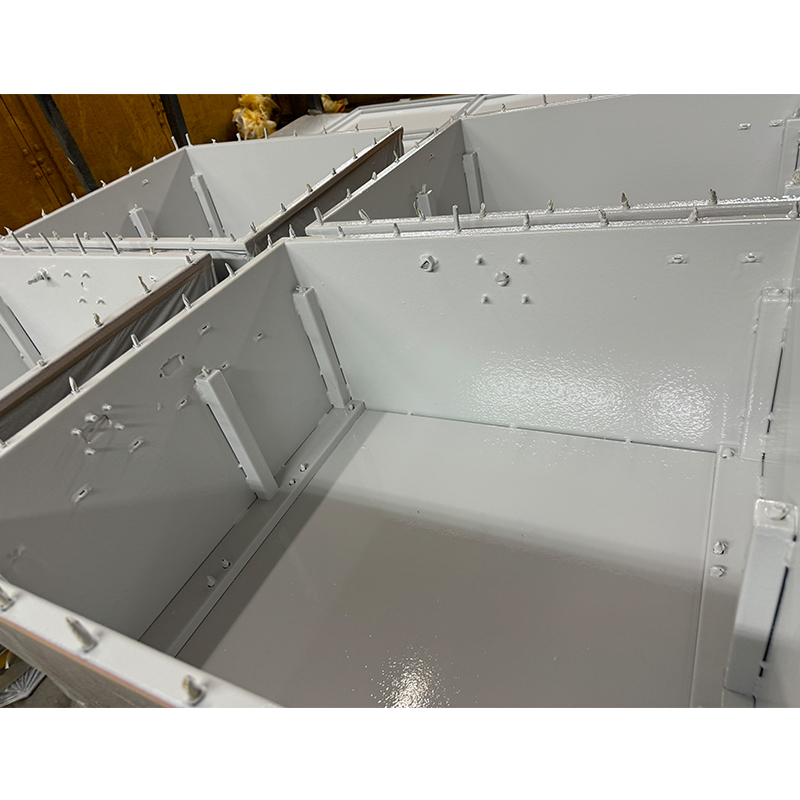

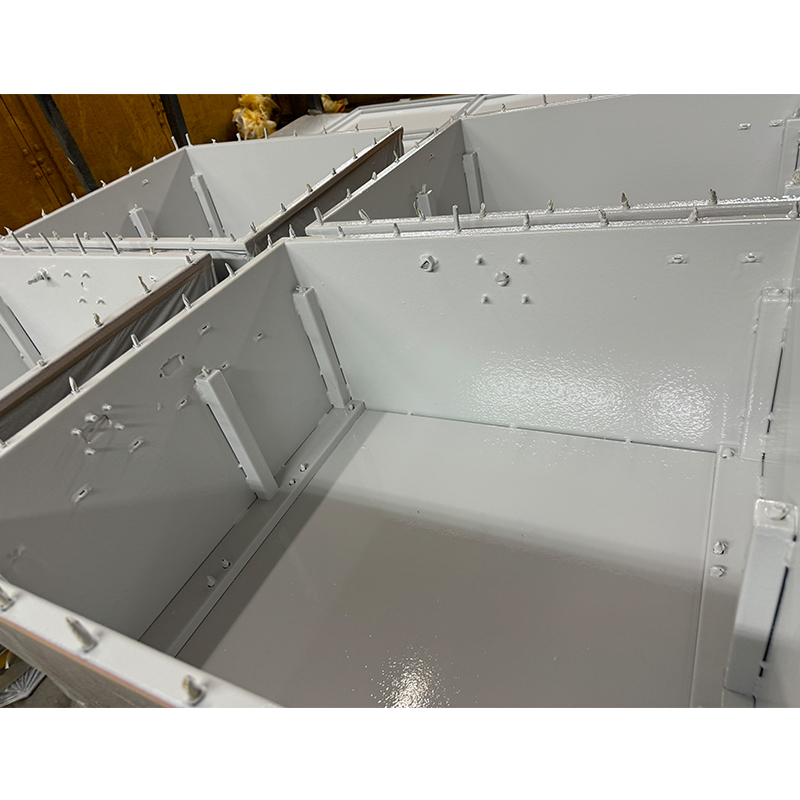

4. Application Scenario Verification: Comprehensive Coverage from Fine to Coarse ApplicationCable Fireproofing: In narrow cable trays where manual brushing is often necessary, this material, with its excellent wetting and thixotropic properties, can evenly cover the cable surface, forming a complete fire barrier.New Energy Battery Boxes: Automated production lines utilize high-pressure air-assisted spraying to achieve ±10μm film thickness control, meeting both lightweight and high protection requirements.Building Steel Structures: On-site touch-ups are often done manually, while the main structure is machine-sprayed. Thanks to the consistency of the material, there are no color differences or performance variations at the joints, ensuring a uniform overall fire resistance rating.5. Seamless Continuous Protection: A Balance of Safety and AestheticsRegardless of the construction method, the final coating is a seamless, overlap-free continuous film, eliminating the weak points of traditional roll or spliced fireproof materials. Its smooth and dense surface possesses an industrial aesthetic, requiring no additional decorative layer, making it particularly suitable for public buildings or high-end equipment where visual appeal is crucial.

Flame-retardant thermal insulation protective materia, through its high-solids formula, intelligent rheology control, and rapid curing technology, truly achieves "construction tailored to local conditions, consistent quality at all times." It ensures that construction is no longer a variable in performance, but rather a guarantee of reliable delivery—in fire protection projects where safety is paramount, this is precisely the most valuable aspect of "consistency."