How does PLA-SLIK consumable achieve the aesthetic effect of "finished product immediately after printing"?

Publish Time: 2026-01-08

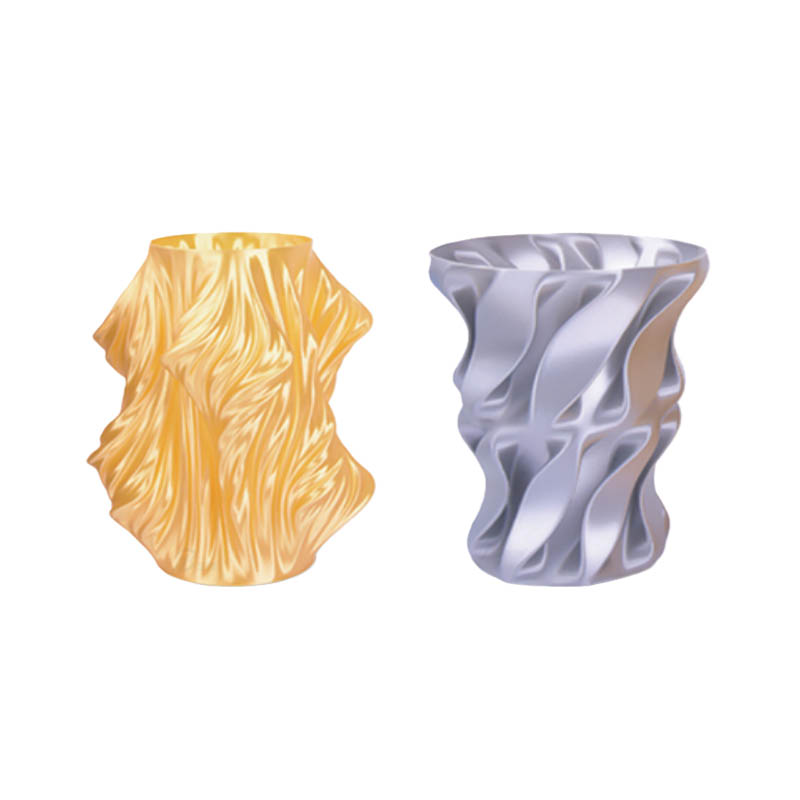

In the field of 3D printing, users often face a dilemma: pursuing high precision and complex structures, yet having to accept rough layer textures, dull surfaces, and complicated post-processing steps—sanding, painting, polishing—which are time-consuming and labor-intensive. The emergence of PLA-SLIK consumable is quietly changing this situation. With its unique material formula and surface properties, it allows printed parts to exhibit a milky smooth texture and a pearly luster the moment they leave the platform, truly achieving the aesthetic effect of "finished product immediately after printing," bringing unprecedented efficiency and beauty to applications such as creative design, figurine making, and home decoration.1. Unique Composite Formula: The Source of Gloss and DelicacyPLA-SLIK is not a simple dyed version of ordinary PLA, but rather a high-purity polylactic acid substrate precisely doped with special modifiers and optically reinforcing microparticles. These additives include nano-sized pearlescent pigments, flexible polymer toughening phases, and surface leveling agents. During melt extrusion, pearlescent microparticles are uniformly dispersed within the PLA matrix, forming a microscopic light-scattering structure. Meanwhile, leveling agents reduce the surface tension of the melt during the printing cooling stage, promoting more natural fusion and spreading of each layer. This "inherent" gloss differs from the external effects of spraying or electroplating; it is a soft pearlescent sheen emanating from the material itself, presenting a consistent and warm visual texture from any angle.2. Ultra-fine Surface Texture: Say Goodbye to Visible Layer TexturesTraditional PLA prints often exhibit noticeable layer textures, especially on curved or large flat areas. PLA-SLIK, by optimizing molecular chain flexibility and crystallization behavior, allows the molten filament to more fully "self-heal" after deposition. Combined with its excellent interlayer adhesion, the boundaries between adjacent layers are almost invisible.3. Maintaining PLA's Core Advantages: Uncompromising Ease of UseSurprisingly, such superior surface performance is not achieved at the expense of printing performance. PLA-SLIK fully inherits the easy-to-print characteristics of PLA filaments: low shrinkage, no warping, and a wide printing temperature window, suitable for most FDM/FFF desktop printers. It has low requirements for the printing platform, requiring no heated bed or enclosed chamber, making it easy for beginners to use. At the same time, its strong interlayer bonding ensures the mechanical reliability of structural components, making it both aesthetically pleasing and practical, breaking the stereotype that "high aesthetics = fragility."4. "Ready-to-Print": Reshaping the Creative and Production ProcessThis feature greatly simplifies the path from design to finished product. Designers can directly deliver PLA-SLIK-printed jewelry prototypes, lamp housings, or art pieces to clients, saving hours of post-processing time; student works from educational institutions can be exhibited without additional embellishment; small studios can even take orders in a "zero-post-processing" mode, improving delivery efficiency and profit margins. More importantly, its environmentally friendly and biodegradable properties, along with its low-odor printing process, make it suitable for use in both home and office environments.5. Diverse Expressions of Color and GlossPLA-SLIK offers a variety of color options, each with a subtle pearlescent undertone—white like solidified cream, black like ink jade, pink like the morning sun, and metallic colors shimmering with understated luxury. This restrained yet sophisticated luster far surpasses the plasticky feel of ordinary glossy PLA, approaching the texture of ceramics, jade, or high-end cosmetic packaging, providing a completely new material language for creative expression.The success of PLA-SLIK consumable lies not only in its material improvement but also in its upgrade of the 3D printing aesthetic paradigm. It proves that functionality and artistry can coexist, and efficiency and refinement need not be sacrificed. When a piece is removed from the printing platform already radiant, creators can focus more on the creative idea itself, rather than tedious embellishments. This is the true value behind "ready-to-work" printing—allowing technology to gently serve beauty.