How does PLA-SLIK consumable achieve a high-gloss, delicate silk-like surface while maintaining the printability of PLA?

Publish Time: 2026-02-16

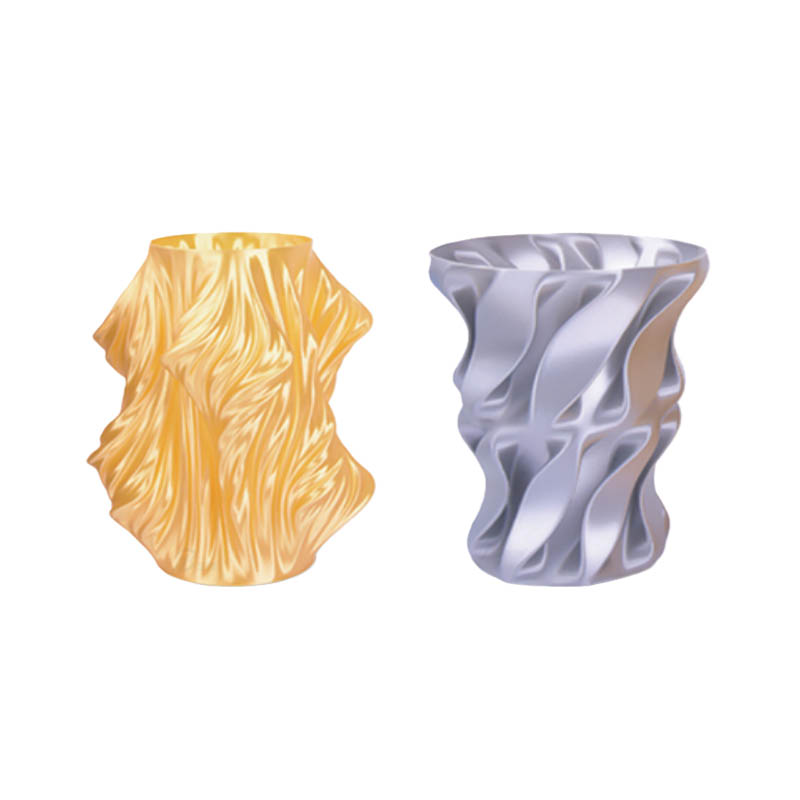

In today's 3D printing consumables market, where functionality and aesthetics are constantly being pursued, PLA-SLIK consumable, as an innovative polylactic acid material with a silk-like texture, successfully bridges the gap between "ease of use" and "premium feel." It not only inherits the excellent printing characteristics of standard PLA, such as low warpage, no heated bed required, and strong interlayer adhesion, but also, through a unique formula and process, gives printed parts a visual and tactile experience as smooth as milk and as lustrous as pearls. This seemingly contradictory combination of performance—both easy to print and aesthetically pleasing—stems from the exquisite synergy of materials science, rheological control, and surface engineering.1. Precise Control of PLA Substrate: Laying the Foundation for Easy PrintingPLA-SLIK uses high-purity PLA resin with a narrow molecular weight distribution as its matrix, ensuring that its glass transition temperature and melt index are within the ideal range. This allows the filament to achieve good flowability at standard printing temperatures of 190–210℃, while cooling rapidly to effectively suppress thermal deformation and warping. More importantly, its crystallization rate is deliberately controlled at a low level to avoid stress accumulation caused by rapid crystallization, thus maintaining the inherent dimensional stability and high success rate of PLA, making it especially suitable for novice users or long-term unattended printing.2. Composite Additive System: Constructing the Core of Silky TextureThe "silky" feel of PLA-SLIK does not come from a post-coating process, but is inherent in the material itself. Its key technology lies in blending a specific ratio of high-refractive-index microparticles and flexible polymer modifiers. On one hand, nano-sized silica or mica derivatives are added, which are uniformly dispersed in the PLA matrix during melt extrusion, forming micron-sized light scattering centers; when light is incident, soft diffuse reflection and weak interference occur, exhibiting an iridescent luster similar to mother-of-pearl. On the other hand, the introduction of a small amount of bio-based elastomers improves elongation at break without significantly reducing rigidity, resulting in a denser surface, stronger resistance to microcracks, and a smooth, non-brittle feel.3. Melt Rheology Optimization: Achieving Layer Concealment and Surface Self-FusionThe key to a high-gloss surface lies in the ability of the molten filaments to fully spread and fuse adjacent paths during deposition. PLA-SLIK optimizes the viscoelastic properties of the melt by adjusting the interfacial compatibility between the additives and PLA—the viscosity decreases moderately under shearing, facilitating fine material output; and the elastic modulus is rapidly restored after deposition, preventing collapse. Simultaneously, its surface tension is slightly lower than that of ordinary PLA, making it easier for the molten filaments to wet the printed layers, reducing interlayer gaps and "orange peel" texture.4. Post-processing User-Friendliness and Application AdaptabilityThanks to its dense, non-porous surface structure, PLA-SLIK prints can be used directly in aesthetically demanding scenarios such as display models, jewelry prototypes, and home décor without sanding or painting. Its gloss effect subtly changes under different lighting angles, enhancing its three-dimensionality and premium feel. Simultaneously, because it does not use volatile plasticizers or halogenated flame retardants, the material retains PLA's bio-based properties and compostability potential, aligning with environmental trends.The success of PLA-SLIK consumable marks a leap in 3D printing materials from simply "usable" to "enjoyable." Through molecular design, microstructure control, and process matching, it retains PLA's ease of use while endowing creations with a silky sensory appeal. This is not merely a victory in material formulation, but a vivid embodiment of user-experience thinking in additive manufacturing—making every print a dual enjoyment of sight and touch.