How does flame-retardant thermal insulation protective materia construct a triple barrier of "fire resistance + corrosion resistance + aesthetics" in new energy battery boxes?

Publish Time: 2026-01-15

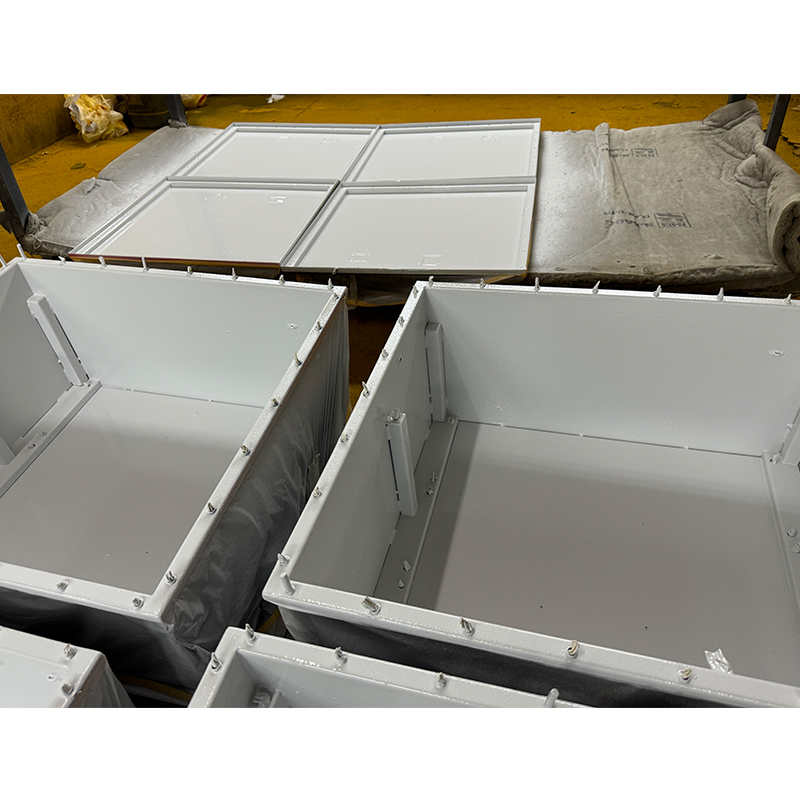

With the rapid development of industries such as new energy vehicles and energy storage power stations, the safety of power battery systems has increasingly become a core concern in the industry. Among these concerns, the fire risk caused by battery thermal runaway is particularly prominent—once a single cell short-circuits or overheats, it can spread to the entire battery module within seconds, releasing a large amount of heat and flammable gases, causing serious safety accidents. Flame-retardant thermal insulation protective materia, with its unique material design and construction adaptability, constructs a high-performance protective barrier on the surface of new energy battery boxes that integrates "fire resistance, corrosion resistance, and aesthetics."1. Fire Resistance: From Passive Flame Retardant to Active Thermal InsulationThis flame-retardant thermal insulation protective materia adopts a two-component reactive system, which, after curing, forms a dense, continuous polymer network structure containing highly efficient intumescent or halogen-free flame retardants. When exposed to high temperatures or flames, the coating rapidly expands and carbonizes, forming a low-thermal-conductivity insulating carbon layer that effectively slows heat transfer to the battery box interior and inhibits thermal runaway. Simultaneously, its high limiting oxygen index means it produces almost no molten droplets or toxic fumes during combustion. More importantly, the coating possesses certain thermal insulation properties, maintaining the temperature difference between the outer surface and interior of the box within a safe threshold for a short period, providing valuable response time for the battery management system.2. Corrosion Protection: Seamless Coverage Resists Corrosion in Complex EnvironmentsNew energy battery boxes are often deployed outdoors, in underground garages, or in industrial environments, exposed to moisture, salt spray, acid rain, and chemical pollutants for extended periods, posing a serious corrosion threat to the metal casing. Traditional coatings are prone to localized corrosion due to pinholes, seams, or insufficient adhesion, thus affecting structural strength and electrical safety. This high-solids-content special topcoat, with a solids content exceeding 80%, forms a seamless, dense, and highly cross-linked continuous protective layer after film formation, significantly improving its barrier capabilities against moisture, chloride ions, and corrosive media. Its excellent scratch resistance and mechanical strength also withstand physical damage during transportation, assembly, or maintenance, ensuring long-term stable protection.3. Aesthetics: Balancing Functionality and Visual ExperienceWhile meeting stringent performance requirements, this material does not sacrifice aesthetic quality. The coating surface is smooth and flat, available in a variety of colors, and its gloss level is controllable, meeting the consistency requirements of OEMs or project owners for product appearance. Especially in high-end electric vehicles or commercial energy storage systems, battery boxes are often visible components; an aesthetically pleasing coating not only enhances the overall texture but also conveys the brand's emphasis on safety and detail. Furthermore, because it is suitable for various application methods, including hand brushing, traditional air spraying, and even high-pressure air-assisted spraying, it can achieve uniform coverage even in complex corners or weld areas, avoiding visual imperfections caused by patchwork repairs.4. Rapid Curing, Adapting to Efficient Manufacturing ProcessesFor large-scale production, the material's rapid curing characteristics greatly improve application efficiency. Under normal temperature or moderate heating conditions, it reaches transportable strength within hours and fully cures within 24 hours, compatible with existing production line cycles. High solids content also means less material used per unit area and lower VOC emissions, aligning with green manufacturing trends.Flame-retardant thermal insulation protective materia are no longer just an "additional coating," but a crucial component of the battery system's safety architecture. This new generation of two-component, high-solids-content flame-retardant special topcoat, through the deep integration of materials science and engineering applications, successfully achieves a triple unity of fire resistance, corrosion resistance, and aesthetics in new energy battery boxes. It serves as both an "invisible shield," safeguarding the safety boundaries of the energy core, and a "refined outer layer," showcasing the pursuit of high-end manufacturing quality.